There’s More Than One Way to Build a Wind Turbine

You’d be forgiven for assuming that wind energy is a technologically stagnant field. After all, the sleek, three-blade turbine has defined the industry for nearly half a century. But even with over 1,000 gigawatts of wind generating capacity installed worldwide, there’s a group of innovators who still see substantial room for improvement.

The problems are myriad. There are places in the world where the conditions are too windy and too volatile for conventional turbines to handle. Wind farms must be sited near existing transportation networks, accessible to the trucks delivering the massive components, leaving vast areas with fantastic wind resources underdeveloped. Today’s turbines have around 1,500 unique parts, and the infrastructure needed to assemble and stand up a turbine’s multi-hundred-foot tower and blades is expensive— giant cranes don’t come cheap.

“We’ve only really ever tried one type of technology,” Neil Rickner, the CEO of the wind power startup Airloom Energy, told me. Now, he’s one of a few entrepreneurs trying a new approach.

Airloom’s system uses much-shorter vertical blades attached to an oval track that resembles a flat rollercoaster — no climbs or drops, just a horizontal loop composed of 58 unique parts. Wind propels the blades around the track, turning a vertical shaft that’s connected to an electricity-producing generator. That differs from conventional turbines, which spin on a vertical plane around a horizontal shaft, like a ferris wheel.

The system is significantly lower to the ground than today’s turbines and has the ability to capture wind from any direction, unlike conventional turbines, allowing for deployment in areas with shifting wind patterns. It promises to be mass manufacturable, cheap, and simple to transport and install, opening up the potential to build systems in a wider variety of geographies — everywhere from airports to remote or even mountainous regions.

Airloom’s CTO, Andrew Street, brings a background in drone tech that Rickner said helped shape the architecture of Airloom’s blades. “It’s all known tech. And it’s not completely off the shelf, but Andrew’s done it on 17 other platforms,” he told me. Rickner himself spent years at GoogleX working on Makani, a now-defunct wind energy project that attempted to commercialize an airborne wind energy system. The concept involved attaching rotors to autonomous kites, which flew in high-altitude loops to capture wind energy.

That system ultimately proved too complicated, something Airloom’s founder Robert Lumley warned Rickner about a decade ago at an industry conference. As Rickner recalls, he essentially told him, “all of that flying stuff is too complicated. Put all that physics — which is great — put it on the ground, on a rail.” Rickner took the lesson to heart, and when Lumley recruited him to join Airloom’s team a few years ago, he said it felt like an ideal chance to apply all the knowledge he’d accumulated “around what it takes to bring a novel wind technology to a very stodgy market.”

Indeed, the industry has proven difficult to disrupt. While Airloom was founded in 2014, the startup is still in its early stages, though it’s attracted backing from some climate sector heavyweights. Lowercarbon Capital led its $7.5 million seed round in 2024, which also included participation from Breakthrough Energy Ventures. The company also secured $5 million in matching funds from the state of Wyoming, where it’s based, and a $1.25 million contract with the Department of Defense.

Things are moving now. In the coming months, Airloom is preparing to bring its pilot plant online in Wyoming, closely followed by a commercial demo. Rickner told me the plan is to begin construction on a commercial facility by July 4, the deadline for wind to receive federal tax credits.

“If you could just build wind without gigantic or heavy industrial infrastructure — cranes and the like —- you will open up huge parts of the world,” Rickner told me, citing both the Global South and vast stretches of rural America as places where the roads, bridges, cranes, and port infrastructure may be insufficient for transporting and assembling conventional turbines. While modern onshore installations can exceed 600 feet from the tower’s base to the blade’s tip, Airloom’s system is about a fifth that height. Its nimble assembly would also allow turbines to be sited farther from highways, potentially enabling a more “out of sight, out of mind” attitude among residents and passersby who might otherwise resist such developments.

The company expects some of its first installations to be co-located with — you guessed it — data centers, as tech giants are increasingly looking to circumvent lengthy grid interconnection queues by sourcing power directly from onsite renewables, an option Rickner said wasn’t seriously discussed until recently.

Even considering Trump’s cuts to federal incentives for wind, “I’d much rather be doing Airloom today than even a year ago,” Rickner told me. “Now, with behind-the-meter, you’ve got different financing options. You’ve got faster buildout timelines that actually meet a venture company, like Airloom. You can see it’s still a tough road, don’t get me wrong. But a year ago, if you said we’re just going to wait around seven years for the interconnection queue, no venture company is going to survive that.”

It’s certainly not the only company in the sector looking to benefit from the data center boom. But I was still surprised when Rickner pointed out that Airloom’s fundamental value proposition — enabling wind energy in more geographies — is similar to a company that at first glance appears to be in a different category altogether: Radia.

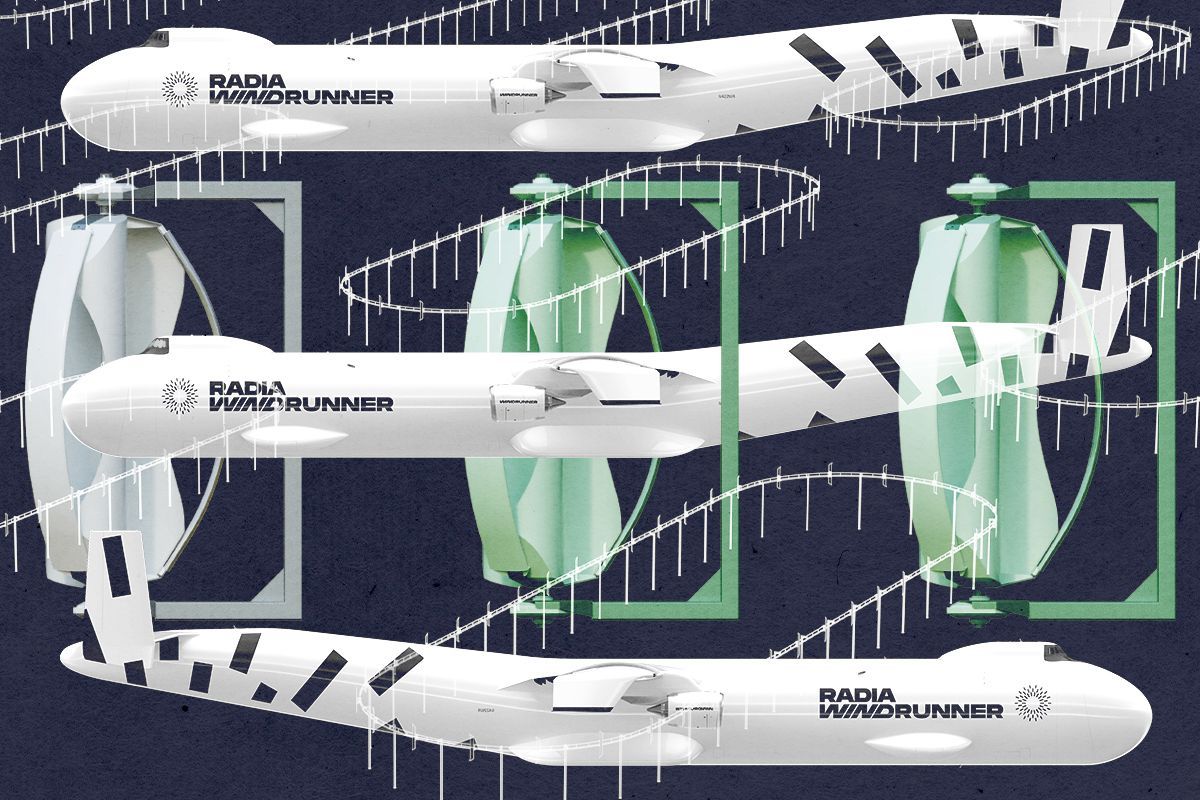

Valued at $1 billion, this startup plans to make a plane as long as a football field to carry blades roughly 30% to 40% longer than today’s largest onshore models. Because larger blades mean more power, Radia’s strategy could make wind energy feasible in low-wind regions or simply boost output where winds are strong. And while the company isn’t looking to become a wind developer itself, “if you look at their pitch, it is the Airloom pitch,” Rickner told me.

Will Athol, Radia’s director of business development, told me that by the time the company was founded in 2016, “it was becoming clear that ground-based infrastructure — bridges, tunnels, roads, that kind of thing — was increasingly limiting where you can deploy the best turbines,” echoing Airloom’s sentiments. So competitors in the wind industry teamed up, requesting logistics input from the aviation industry. Radia responded, and has since raised over $100 million as it works to achieve its first flight by 2030.

Hopefully by that point, the federal war on wind will be a thing of the past. “We see ourselves and wind energy as a longer term play,” Athol told me. Though he acknowledged that these have certainly been “eventful times for the wind industry” in the U.S., there’s also a global market eager for this tech. He sees potential in regions such as India and North Africa, where infrastructure challenges have made it tough to deploy large-scale turbines.

Neither Radia nor Airloom thinks its approach will render today’s turbines obsolete, or that other renewable resources will be completely displaced. “I think if you look at most utilities, they want a mix,” Rickner said. But he’s still pretty confident in Airloom’s potential to seriously alter an industry that’s long been considered mature and constrained to incremental gains.

“When Airloom is 100% successful,” he told me, “we will take a huge chunk of market share.”